|

|

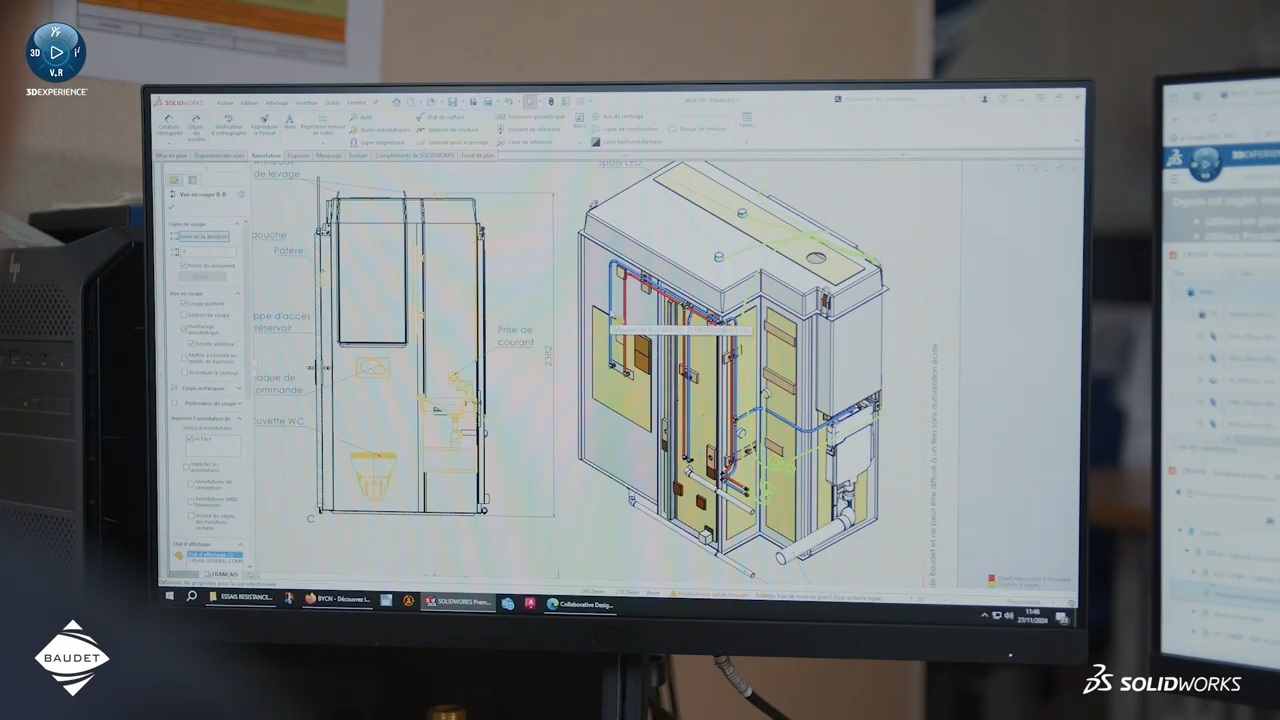

BAUDET(https://baudet-sa.com/en/) has specialized in manufacturing and delivering prefabricated, fully finished, ready-to-install bathroom units to sites across Europe for over three decades. To keep pace with today’s sustainability-driven building environment, BAUDET turned to SOLIDWORKS and the 3DEXPERIENCE platform to enable it to push the boundaries of modular construction.

“Today, this prefab bathroom solution allows us to deliver a fully finished factory product to a work site,” says BAUDET Executive Vice President Laurent Roué. BAUDET builds 6,000 prefab bathrooms per year off-site in a controlled factory environment, which enables better quality control, faster installs, and less disruption on job sites. Prefab bathrooms typically save time, cut costs, and simplify the entire construction process.

BAUDET’s roots are in polyester construction, but the company is always seeking innovations and opportunities. “About 10 years ago, we developed a second concept, a metal-framed bathroom, which allows us to size bathrooms according to the needs of the site and adapt the finishes according to the requirements of project developers and architects,” adds Roué.

To meet the growing complexity of these modular projects, BAUDET partnered with Dassault Systèmes to integrate SOLIDWORKS and the 3DEXPERIENCE into their workflows. The result is a connected ecosystem that unites design, manufacturing, and on-site construction through a shared digital thread, a connected process that links every stage of a product’s life cycle, keeping everyone on the same page with real-time data.

Vincent Carton, Chief Project Manager at BRIC Construction (BAUDET’s construction partner), explains: “To do this, we use a digital twin of the construction, where we input [into] a common data environment.” For BRIC, this digital collaboration is one way to reduce carbon impact while increasing productivity.

Carton describes how this looks in practice: “The collaborative project with BAUDET allowed us to integrate these bathroom models into the digital twin and retrieve their exact geometry and the interface points with the cable chase and the kitchenette.” That level of accuracy made it possible to prebuild cable chases. (Interface points are where different parts of a building must fit and integrate, such as where a bathroom connects to a structure’s pipes or where a kitchen connects to a building’s wires.)

The ability to resolve interface challenges before hitting a job site has proven transformational. “Project workers began to resolve these interfaces right from the design stage by modifying the connection points with the bathrooms or the pathways in the cable chase,” says Carton. “For example, being able to anticipate the interfaces allowed our teams to create the 235 cable chases in a micro factory at the base of a work site and to install them before major construction began.”

SOLIDWORKS plays an equally critical role inside BAUDET. “SOLIDWORKS software allows us to be very proactive in terms of design and development and sharing information about our bathrooms with our various stakeholders,” notes project manager Emmanuel Philippe. The team also uses SOLIDWORKS Simulation to test structural resistance, which helps to accelerate prototyping and shorten production cycles. “So, we can be more responsive during testing, prototyping, and production runs,” he adds.

The seamless link between Dassault Systèmes SOLIDWORKS and 3DEXPERIENCE means fewer surprises and more synergy on complex, multi-contractor projects. “There are a lot of contract lots [scopes of work] associated with our bathroom module,” Philippe continues. “So, this allows us to use 3DEXPERIENCE to place our bathroom module and integrate it with the building’s digital model.”

BAUDET’s internal workflows now mesh more effortlessly with those of global contractors like Bouygues and other major firms. Roué sums up the value of the partnership: “The advantage of 3DEXPERIENCE is that it has a collaborative platform that lets us speak the same language.”

With roughly 20 pod models already developed or underway, BRIC Construction and BAUDET are proving how standardization and customization can work hand-in-hand. “Our goal is for the interfaces with these pods to already be resolved based on what we’ve learned about the building site,” emphasizes Carton.

Whether adapting design tools to the construction sector or closing the gap between offsite manufacturing and onsite assembly, BAUDET’s journey is proof that digital transformation in construction is both practical and a bottom-line reality. Philippe concludes, “We are working more efficiently with SOLIDWORKS tools and all the related modules linked to SOLIDWORKS.”

|

|

|小黑屋|手机版|Archiver|机械荟萃山庄

( 辽ICP备16011317号-1 )

|小黑屋|手机版|Archiver|机械荟萃山庄

( 辽ICP备16011317号-1 )